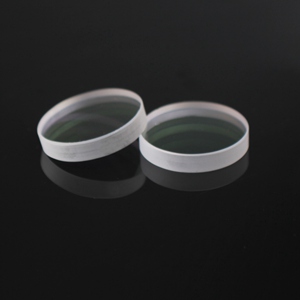

The reflector is an optical element that reflects the incident light by coating a metal silver or aluminum film or dielectric film on the back of the optical glass by vacuum coating. The use of a high reflectance mirror can double the output power of the laser ,and is reflected by the first reflective surface, the reflected image is not distorted, and there is no ghosting.

Oxygen-free copper materials are usually used in high-power laser systems due to their high thermal conductivity.

| Diameter | Thickness | Material | Wavelength | Reflectivity |

| 25mm | 3mm |

Oxygen-free copper |

10.6um | ≥99% |

| 38mm | 6mm |

Oxygen-free copper |

10.6um |

≥99% |

| 50mm | 10mm |

Oxygen-free copper |

10.6um |

≥99% |

| 50mm | 25mm |

Oxygen-free copper |

10.6um |

≥99% |

| 50.8mm | 5.1mm |

Oxygen-free copper |

10.6um |

≥99% |

| 50.8mm | 9.5mm |

Oxygen-free copper |

10.6um |

≥99% |

| 60mm | 10mm |

Oxygen-free copper |

10.6um |

≥99% |

| 70mm | 25mm |

Oxygen-free copper |

10.6um |

≥99% |

| 76.2mm | 6.4mm |

Oxygen-free copper |

10.6um |

≥99% |

Key Features:

- Material: High-grade copper with precision-machined surfaces

- High Reflectivity: Optimized for CO2 lasers and infrared applications

- Thermal Stability: Superior heat dissipation for long-term usage in high-power systems

- Durability: Scratch-resistant and corrosion-resistant coating for extended lifespan

- Customizable Options: Available in various sizes, thicknesses, and coatings

- Applications: Laser cutting, welding, optical systems, and scientific instruments

Applications:

The High Quality Copper Reflective Mirror is widely used in

- CO2 laser systems for cutting, welding, and marking

- Optical instruments requiring high reflectivity and thermal stability

- Industrial applications involving high-power laser systems

- Scientific research and optical experiments

Changchun Realpoo Photoelectric Co.,Ltd.

Changchun Realpoo Photoelectric Co.,Ltd.